How Industry 4.0 Improves Manufacturing Employee Productivity: Part 1 of 3

Performance Evaluation Tool

The best managed companies are those that work based on goals. Their goals are measurable, aggressive but achievable and always include Cost, Quality and Efficiency. Employees in these companies are highly driven and share a common purpose.

Your company is only as good as your employees. To achieve your goals, make sure all employees are aware of them and understand how they can contribute and play a part in the big picture. Provide constant training that makes them Subject Matter Experts in their roles. In today’s market, it is difficult to attract talented employees, so make sure you have a process to develop talent and another to retain it.

The employee evaluation process is a powerful instrument to improve employee performance by providing evidence-based feedback. The evaluation tool must be objective and trusted by all employees. The tool should be available to each employee on demand so they can review their performance and take corrective actions to improve it. This eliminates surprises when the employee sits with his/her supervisor during performance review.

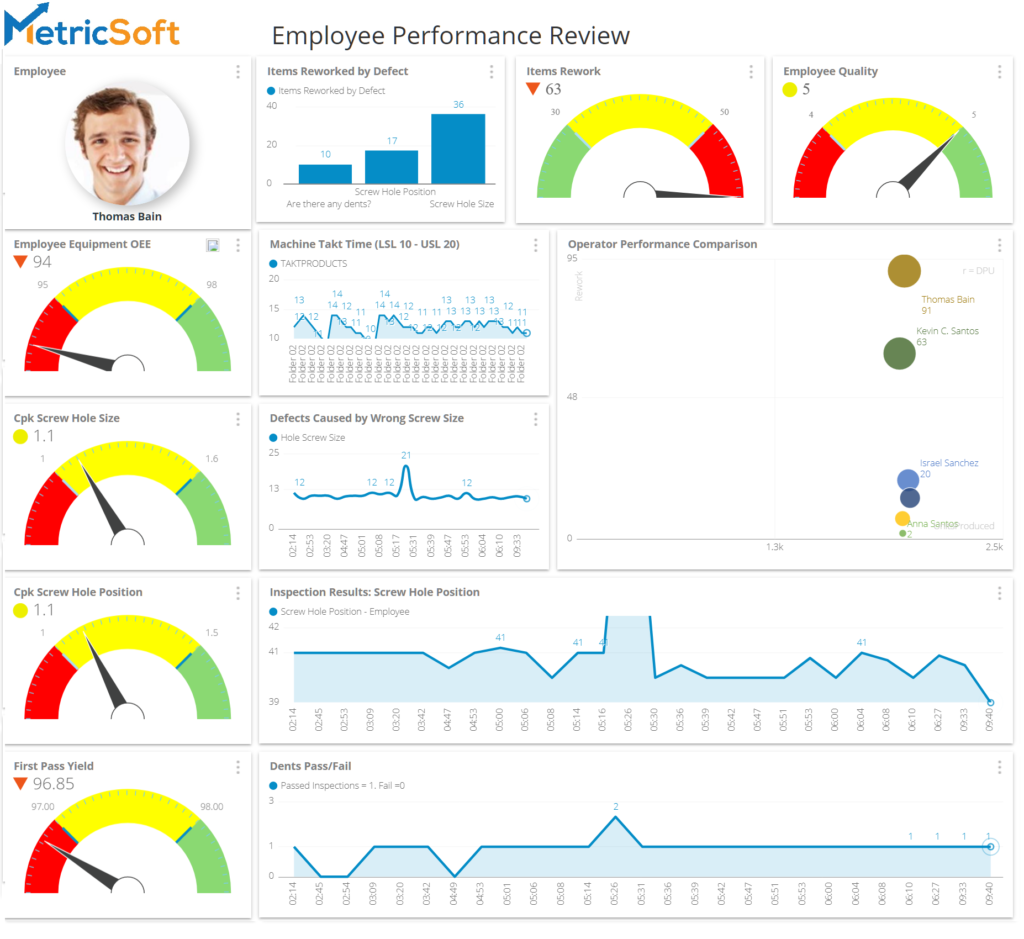

The evaluation process can be very contentious when there is a discrepancy in the evaluation assessment between the employee and their leader. To avoid this, MetricSoft keeps a personal dashboard for each production operator that tracks their personal contribution to your goals, KPI and Metrics. Each time a Control Plan or Inspection is executed, MetricSoft tags the results to the employee. The dashboard can include additional metrics specific to the operator such as Work Time Availability, Waste, Quality, etc.

You can use MetricSoft Employee Dashboards to create incentive plans to motivate and reward your employees based on their true performance and goals contribution. Considerations for an effective Incentive Program will be covered in our next blog.

Key items to include in your Employee Personal Performance Dashboard.

When developing an effective Employee Performance Monitoring tool, make sure that the following are considered:

- Goal settings: Make sure you set goals for each of your processes and that these are tied to the company’s overall objective. Always include Quality, Delivery SLA, and Cost, these are the three factors your customers are interested in.

- Measuring: This is the base for all performance management tools. There is a saying that goes “If you don’t measure it, you can’t improve it.”. Your monitoring tool must measure each of your process KPI and Metrics and with Industry 4.0, results are available in real-time. Also, the employee evaluation or monitoring tool must include their personal contribution to each KPI and Metric.

-

Real-Time Results: Employee Performance must be available in real-time. All employees should be able to monitor their performance during production and take corrective actions for improvement.

-

Employee Trust: This is by far the most critical consideration of your Performance Monitoring Program; your employees must trust the results otherwise there will be constant contentions and disagreement. Make sure to solicit feedback from your employees when developing the monitoring solution and avoid the classic mistake of just throwing the solution at them without giving them the benefit of taking part in the design process. If you do this, they will own the tool and have a higher degree of trust.

Always safeguard the integrity of your data by eliminating, as much as possible, manual data entry especially data required to calculate performance. One of the advantages of Industry 4.0 is that it taps directly into the equipment to pull the data required to automatically calculate your KPI and Metrics. Industry 4.0 also uses manual execution of Process Control Plans by using tablets, but in a controlled manner that reduces data entry issues.

- 360 Evaluation: Your employee evaluation must measure all possible issues that can affect overall product quality. Keep in mind almost all quality issues are created by at least one of the following: 1) an employee did not do his/her job, 2) an employee did his/her job wrong and/or 3) an employee did his/her job late.

The following image of a Personal Employee Dashboard includes the following:

- Employee Productivity

- Employee Quality

- Employee Re-work

- Employee First Pass Yield

- OEE personalized to employee equipment operation.

- Product Quality Inspections results and technical specifications using Cpk.

- Employee 3D Bubble Chart Employee Performance comparison. The use of this chart will be explained in our next blog on Training for Result.

Note: This list is not exhaustive, MetricSoft can also track employee metrics for; Work Time Availability, Mean Time Between Job, Mean Time Between Failure, etc.

When creating dashboard for employee consumption, it is a good idea to use RAG (Red, Amber, Green) to quickly highlight results. Notice that this employee is not trending in the right direction with some of his KPI like Rework, OEE, First Pass Yield, etc. The Operator Performance Comparison Bubble Chart shows he is trailing in productivity and quality compared to his colleagues. This detail level of employee performance can be used to develop custom training programs for your employees. Training will be discussed in our blog for Training for Results.